Spray foam insulation can dramatically affect how an ultra-tight building envelope performs by reducing uncontrolled air movement and adding thermal resistance. In modern construction, comfort and efficiency often depend on limiting air leakage as much as on increasing R-value, and spray foam addresses both when installed correctly. The result is a home that holds conditioned air longer, experiences fewer drafts, and sees less temperature drift between cycles. At the same time, tighter envelopes shift how moisture behaves. Water vapor that once escaped through cracks can remain inside longer, and assemblies that dry slowly may need different design choices to avoid condensation risks. Spray foam performance should be evaluated as a system outcome, not just a product number, because the benefits and pitfalls are tied to ventilation strategy, HVAC sizing, and how the wall or roof assembly manages drying. When these factors align, spray foam supports steady comfort and predictable energy use.

Air sealing changes everything.

- Air sealing value and thermal stability in tight homes

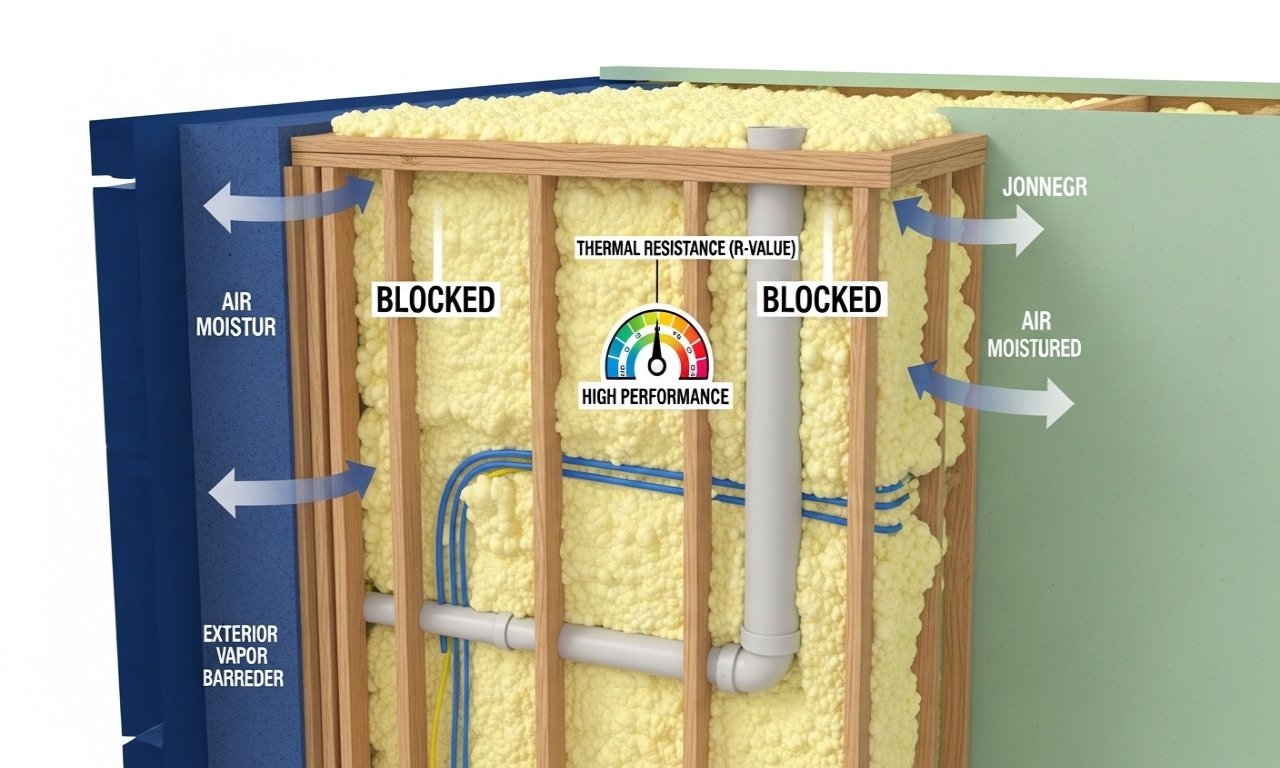

The largest performance shift from spray foam often comes from air sealing rather than pure insulation value. By reducing convective heat transfer, spray foam limits the way outside air sneaks in and conditioned air leaks out through gaps at rim joists, top plates, penetrations, and irregular framing cavities. In ultra-tight envelopes, this creates a more stable indoor environment, with hot and cold spots less driven by random drafts. Thermal stability improves because the building no longer relies on the HVAC system to correct air leakage. Spray foam can also help in complex framing areas where batts are difficult to fit perfectly, reducing the risk of voids that become hidden bypass channels.

However, this same air sealing effect means the home must rely on intentional ventilation to maintain indoor air quality and moisture balance. The envelope becomes more predictable but less forgiving of missing exhaust fans, oversized range hoods, or poorly balanced fresh-air systems. Contractors often test the air tightness after installation to confirm that targets are met without over-sealing areas that still need controlled drying paths. When air sealing is paired with proper ventilation. The home feels quieter, more even, and less reactive to outdoor wind and temperature changes.

- Open cell versus closed cell behavior and moisture considerations

Spray foam type matters because open cell and closed cell foams behave differently with vapor and drying. Open-cell foam provides strong air sealing and sound reduction, but it is more vapor permeable, allowing assemblies to dry through it under certain conditions. Closed-cell foam has a higher R-value per inch and acts as a stronger vapor retarder, which can be useful in some climates and assemblies, but it can also reduce drying potential if used in the wrong place. The right choice depends on climate, roof design, and whether the assembly needs inward or outward drying.

In humid regions, controlling vapor drive and preventing condensation on cold surfaces are priorities, especially in air-conditioned homes where interior surfaces can be cool. In mixed climates, seasonal reversals complicate decisions, so installers coordinate with the designer and HVAC plan. A Houston Spray Foam Insulation Contractor may focus heavily on moisture strategy because long cooling seasons and high humidity demand assemblies that resist condensation while still allowing controlled drying. Install quality is also critical. Poor mixing, incorrect lift thickness, or inadequate curing time can cause shrinkage, gaps, or odors, undermining performance and creating indoor air quality concerns. Foam performance is therefore tied to both product selection and disciplined installation practices.

- HVAC interaction and comfort in ultra-tight envelopes

Spray foam changes heating and cooling loads, which affects HVAC performance. In many projects, air sealing and insulation reduce peak loads enough that oversized equipment becomes a risk. Oversized systems can short-cycle, reducing dehumidification and creating a cool but clammy comfort. Proper load calculations become more important after spray foam upgrades because envelope improvements may significantly reduce the required capacity. Air distribution becomes more noticeable, too. With fewer drafts masking issues, imbalanced ducts or weak return pathways can stand out.

Spray foam applied to the roof deck can also bring ductwork and air handlers into a semi-conditioned attic space. Reducing duct losses and improving delivered air temperatures, but only if the attic is truly within the thermal and air boundary. If the attic remains leaky or poorly ventilated, heat and moisture can still accumulate. Mechanical ventilation is often required in ultra-tight homes to maintain fresh air and manage indoor pollutants. Spray foam projects should consider where the ventilation air is introduced and how it is tempered. When all systems are aligned, spray foam supports quieter operation, steadier temperatures, and fewer extreme runtime swings because the home is no longer fighting uncontrolled infiltration.

Spray foam insulation performance in ultra-tight building envelopes is driven by its air-sealing impact as much as by its thermal resistance. By reducing infiltration and convective heat loss, spray foam can stabilize indoor temperatures and cut drafts, but it also changes how moisture and indoor air quality must be managed. Choosing between open cell and closed cell foam should reflect climate and drying strategy. Installation quality determines whether gaps, shrinkage, or odor issues undermine results. HVAC sizing, airflow balance, and mechanical ventilation become more important after air sealing because tighter homes require intentional fresh air and reliable humidity control. With careful detailing, testing, and long-term operating practices, spray foam provides consistent comfort and efficient performance without unintended moisture issues.