Introduction

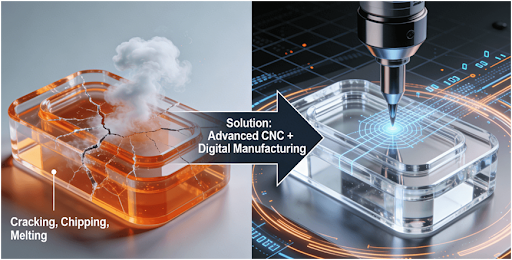

The demand for high-performance acrylic parts is increasing rapidly across industries such as medical devices, consumer electronics, and optics. However, traditional CNCmachining methods result in micro-cracks, a lack of dimensional accuracy, and cost overruns, thus affecting time-to-market. The problem has been process issues specific to the material, where poor tool selection and cooling control do not take into consideration the thermal sensitivity and brittleness of acrylic, resulting in high scrap rates.

The solution herein involves the adoption of advanced CNCmachining technologies incorporated into Digital manufacturing and precision engineering to optimize parameters and supply chain management for highly efficient production. The following sections systematically analyze how to apply these solutions in the manufacturing process.

What Are the Key Challenges in Acrylic CNC Machining?

Machining the acrylic plastic, renowned for its optical clarity and ability to withstand the elements, is no easy task. Conventional machining methods can, if not carefully controlled, introduce a variety of errors.

Thermal Deformation & Surface Defects

Acrylic has a low melting point and is very sensitive to temperature. Friction generated during machining can result in melting or adhesion to the tool. This results in errors during the machining process and the appearance of a cloudy “crazing effect” or burn marks on the acrylic surface. The light transmission properties of the acrylic are significantly affected.

Edge Chipping and Internal Cracks

Acrylic material tends to be brittle by nature, which makes it a problem when executing processes such as drilling, slotting, or machining thin-walled components.

l Mechanical Stress Content

Inadequate feed rates, the presence of a dull tool, and high clamping forces may cause a concentration of stress in the workpiece, thereby initiating micro-cracks.

l Break Burrs

When the drill or end mill exits the workpiece, it is prone to chipping or the development of burrs or gaps on the exiting side because of the absence of engagement with the workpiece. Research carried out by NIST regarding testing standards of polymers underscores the importance of carrying out detailed mechanical tests to grasp the concept of brittle-ductile transitions that influence machining operations.

Limitations of Conventional

Historically, engineers had to resort to trial and error when adjusting the parameters involved. This method, which lacks a systematic process for analyzing and managing the process involved in machining, is inefficient, non-reproducible, and expensive. There is, therefore, a need for a systematic process using a reliable Acrylic CNC Machining Buyer’s Guide to ensure that all the processes involved, from tool selection and process parameters, are optimized.

How Does Advanced CNC Machining Enhance Acrylic Part Quality?

In view of the difficulty in CNC machine precision in acrylic material cutting, some modern technologies in advance CNC machining are introduced to overcome the problem.

The main area of development is related to process control. For example, with 5-axis simultaneous CNC Machining, the machine tool is able to move towards the workpiece at optimal angles, thereby completing the machining of complex shapes in one fixed position itself. There are fewer chances of repositioning errors, and the machining can be done with tolerances of ±0.005mm accuracy. Real-time monitoring systems monitor temperature, machining force, and vibration through sensors to reduce heat and vibration by adjusting spindle speeds and feeds accordingly.

This is the essence of Digital Manufacturing. According to the Society of Manufacturing Engineers (SME) news,, the use of data-driven optimization is one of the important trending topics in the area of smart manufacturing. Through the collection and analysis of machining data, mathematical models can be developed that enable the identification of machine parameter settings that could result in the generation of defects. Thus, the process window can be precisely established. An interesting example from Precision Engineering Stories is that of an optics product manufacturer. They have been able to optimize the production of their transparent acrylic lenses from 65% to above 95% using the advanced machining center with low-temperature cooling.

What Digital Manufacturing Technologies Support Acrylic CNC Processes?

It is the backbone for modern and efficient Manufacturing Solutions, digitally enabling a paradigm change in the production of acrylic parts by knitting together the virtual and physical worlds.

First, seamless CAD/CAM integration is foundational. After a 3D model is finished in CAD, the CAM software automatically generates efficient, collision-free toolpaths and simulates the whole machining process to detect some interference or overheating zones in advance. This right-first-time approach saves a significant amount of material and time spent on test cuts. The application of IoT technology equips machine tools with the ability to “sense” and communicate. Machining parameters, equipment status, and quality inspection data are uploaded in real time to a cloud platform, offering full traceability of the production process. Managers can monitor remotely the progress of multiple orders, while system-issued alerts for data anomalies enable predictive maintenance and quality control.

For those CNC machining companies that are looking for transformation, the adoption of these technologies means a way to hold their competitive edge. Industry data shows that factories can improve more than 20% OEE by adopting digital Manufacturing Solutions, while wastes due to programming errors or improper processes can be reduced by more than 30%. This not only means lower costs but also responsiveness and customization capability.

How to Select a Reliable CNC Machining Supplier for Acrylic Parts?

The selection of the proper manufacturing partner may be the deciding factor in the success of any project involving an acrylic part. There are many CNC machining suppliers, and a set of criteria must be applied.

Technical Capability & Specialized Experiences

The most crucial one is whether it has expertise in acrylic machining. This would entail questions about their availability of machines equipped with precise temperature control systems and diamond tools and experience in handling complex acrylic parts. The quality and professional level of a CNC machining parts factory should be reflected in their high-level technological consultation and process advice rather than merely a quotation.

Quality Management and Certification Systems

Strong quality assurance procedures are a minimum requirement.

l Industry Certifications

Look for certifications such as ISO 9001 (Quality Management) and ISO 13485 (Medical Devices), showing that procedures are standardized. For environmentally responsible customers, ISO 14001 (Environmental Management) is also important.

l Metrology Equipment

Investigate the availability of high precision inspection machines, such as Coordinate Measuring Machines, laser scanners, or optical comparators, within the factory to ensure dimension and geometry checks.

l Quality Control Process

Understand the completeness with regard to the quality control documentation, entailing all aspects from raw material inspection to First Article Inspection and Final Inspection.

Service & Collaboration Model

Leading suppliers provide full Manufacturing Solutions, not merely machining. Assess them on communication effectiveness, project management, and supply chain transparency. Now, there is efficient Online CNC Machining Services where clients can easily upload files, request quotes, and view project status, all of which improves communication effectiveness. In addition, make sure if their expertise covers Design for Manufacturability (DFM) feedback evaluation, for improved designs that lower costs and difficulty of machining.

What Are the Best Practices for Precision Engineering in Acrylic Manufacturing?

The key to successful acrylic machining is a close attention to detail. The best practices listed below are validated based on successful stories of Precision Engineering Stories.

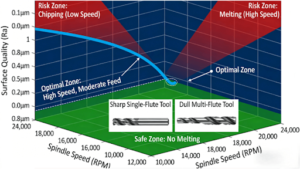

Firstly, the optimization of toolpathing is of utmost importance. The use of climb milling over conventional milling will ensure that the chips are pushed away from the workpiece. Hence minimizing the generation of heat on the surface of the workpiece. When considering profile milling, the use of helical milling, along with low depth of cut, high RPM, and coolant/air mist, will ensure the avoidance of chipping on the edges.

Next, the use of specialized tools becomes vital in the machining process. The use of singleor two-flute end mills, accompanied by the use of polishing diamond tools, will ensure the achievement of a stress-free, mirror-like surface finish.

Moreover, post-processing methods should not be overlooked. Flame polishing/vapor smoothing using a solvent such as dichloromethane is a quick method to remove micro-scratches. The white layer to regain natural optical translucency. Thus, the aforementioned steps constitute a set of skills which form the base for a process called Advanced Manufacturing. It is a method of process control that ensures minimal variations for each CNC machining part.

Conclusion

In a nutshell, it is no longer enough to solve the inherent problems in machining acrylic parts using traditional methods only. The integration of advance CNC machining, Digital Manufacturing solutions, and Precision Engineering Stories principles allows manufacturers to systematically control problems such as thermal deformation, chipping, and surface defects at every level to provide the largest leverage in precision, efficiency, and consistency. The technological path and success stories outlined here provide a verifiable and replicable roadmap for industry advancement.

At a point when the quality, cost, or lead time of acrylic parts becomes the bottleneck of projects, seeking professional support will be a strategic choice. JS Precision offers end-to-end tailored solutions from design optimization to volume production, based on international certifications like ISO 9001, IATF 16949, AS9100D, and ISO 14001, ensuring that each product meets the highest standards of quality. Feel free to contact them-to convert innovative designs into real-life high-quality products.

Author Bio

The author is an expert in precision manufacturing with more than a decade of experience in the optimization of CNC processes. He specializes in Advanced Manufacturing techniques for difficult-to-process materials, such as acrylics, PEEK, and composite materials. He holds a special interest in applying technological advancements to the enhancement of product performance and improvement of manufacturing efficiency for his clients.

FAQs

What is the ordinary tolerance for acrylic in CNC Machining?

A1: Using advance CNC machining techniques, when combined with high-precision spindles and thermal compensation, it is possible to hold acrylic parts to a tolerance of ±0.005mm. In many cases, this can counter thermal expansion issues to satisfy demanding specifications, such as in medical or optical devices.

How may costs in acrylic part manufacturing decrease with digital manufacturing?

A2: Digital Manufacturing minimizes costs by leveraging simulation and data analytics in order to optimize toolpaths and parameters before production, thus avoiding the waste involved in trial and error approaches. Predictive maintenance and process automation can minimize the total scrap rate by as much as 30% by reducing production costs per item substantially.

What kind of defects might occur in acrylic CNC machining work, and how can they he avoided?

A3: Some typical problems are crazing (whitening) and edge chipping. Prevention methods include using sharp, specialized single fluted plastic milling cutters, climb milling while blowing air/misting coolant, and support plates or stratified milling for through-holes. In Stories of Precision Engineering, common themes include optimal exit velocities to prevent chipping in acrylic frames with thin walls.

How can I determine the CNC machining supplier’s ability to produce the acrylic parts?

A4: Potential CNC machining suppliers can be assessed for qualifications in CNC machining through ISO certification, evaluation of competence and equipment with cooling systems for acrylic, analysis of the quality of feedback provided to the designer regarding DFM, and evaluation of case studies about the dependability and competence of the CNC machining service.

How can complex geometries in acrylic material be achieved using advanced CNC machining processes?

A5: Yes, definitely. This is possible with the current state of 5-axis CNC machining. Where angles can be machined on a complex surface, such as creating undercuts, organic curves, and detailed work. When linked with CAM programming in a Digital Manufacturing environment, it guarantees the highest level of surface quality.