Wiring insulation is the thin barrier that keeps electricity traveling where it should and prevents energized conductors from contacting metal parts, wood framing, or human hands. When insulation is intact, it reduces the chance of shocks, arcing, and overheating, even when circuits are heavily used. When insulation is damaged, electrical problems can develop quietly behind walls, above ceilings, or inside panels until a breaker trips, lights flicker, or a burning odor appears. Electricians inspect insulation condition because it reveals how a system has aged, how it was installed, and whether heat, moisture, pests, or mechanical stress have begun to break down materials. This inspection is not only about visible defects, but also about predicting risk by recognizing patterns that often precede failures in residential and commercial buildings.

What insulation checks can uncover?

Insulation damage signals hidden heat and overload issues

One reason electricians focus on insulation is that it records a circuit’s thermal history. Conductors that run hot for long periods can harden or discolor insulation, making it brittle and more likely to crack when moved. Overheated insulation can come from loose terminations, overloaded circuits, undersized conductors, or aging breakers that do not trip consistently under abnormal heat. Electricians look for discoloration near device terminals, melted spots at wire nuts, and insulation that looks shrunken back from a connection. These clues help them pinpoint where resistance heating is occurring, which is often more important than the symptom a homeowner notices, such as warm outlets or intermittent power.

They also check insulation near recessed lights, attic runs, and appliance circuits where heat is common. If insulation is compromised, a conductor can arc to nearby metal or to another conductor, creating a fault that can ignite surrounding materials. Even without a dramatic failure, small arcs can carbonize insulation and create a pathway for further arcing. By inspecting insulation, electricians can correct the underlying causes, such as tightening terminations, redistributing loads, or upgrading wiring methods, before the damage becomes widespread.

Mechanical stress, vibration, and pests leave telltale marks.

Insulation is also inspected because it is often damaged by physical forces rather than pure electrical overload. Wires pulled too tightly through bored holes, stapled too aggressively, or bent sharply at device boxes can develop nicks that are easy to miss but can have serious consequences. Over time, vibration from HVAC equipment, garage door openers, or heavy foot traffic above the ceiling runs can rub insulation against framing or metal edges. In older buildings, brittle insulation can crack simply from normal movement during a device replacement.

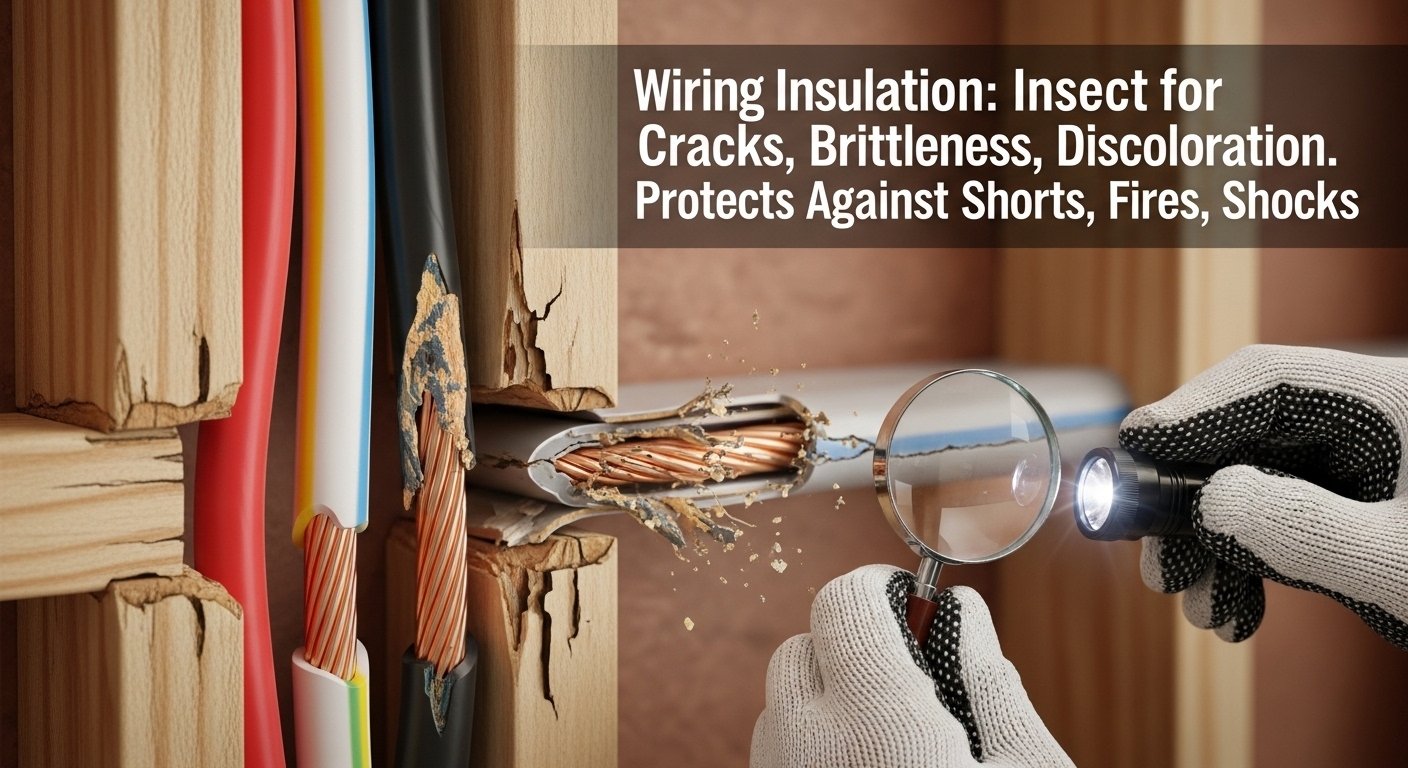

Rodents and insects can chew insulation for nesting material or to clear pathways, leaving exposed copper that is one step away from an arc fault. Moisture adds another risk because wet environments can cause swelling, corrosion of conductors, and insulation breakdown, especially near exterior penetrations, crawl spaces, or basements. Resilient Power & Plumbing often finds that insulation damage is rarely random; it usually clusters around pinch points, junction boxes, and areas where other trades have worked, such as behind renovated kitchens or along added lighting runs. Electricians use these patterns to decide where to open access, what to test further, and how far a repair needs to extend to restore safe coverage.

Why insulation problems can cause unpredictable symptoms

Damaged insulation does not always cause an immediate outage, which is why electricians treat it as a priority during inspections. A conductor may still carry power even when the insulation is partially compromised, and the problem only becomes apparent when temperature rises, humidity changes, or the wire moves slightly. This can create flickering lights, nuisance breaker trips, tingling sensations on metal fixtures, or intermittent device failures that seem to come and go. In multi-wire circuits or shared-neutral situations, insulation damage can interact with loose neutrals, creating voltage swings that harm electronics. Small insulation defects can also allow leakage current, which may not trip a standard breaker but can create heating at contact points or inside wall cavities.

Electricians look for signs such as soot marks near a device box, buzzing sounds, or a hot smell that appears under load. They may use insulation resistance testing in appropriate situations, along with thermal imaging to spot hot spots that correlate with insulation breakdown. Inspecting insulation helps them interpret symptoms correctly, because the visible complaint is often far from the actual defect. A problem at one junction can ripple through a circuit and show up as instability at multiple downstream outlets.

Electricians inspect the condition of wiring insulation because it is a direct indicator of safety, system stress, and the likelihood of future failures. Insulation damage can reveal chronic overheating from loose connections or overload, physical abrasion from poor routing, pest activity, or moisture exposure that accelerates breakdown. These issues often create unpredictable symptoms that appear only under certain loads or environmental conditions, making visual and diagnostic inspection essential. By identifying compromised insulation early, electricians can correct root causes, restore proper conductor protection, and reduce the risk of arcing, shocks, and fire hazards. Insulation checks also help ensure wiring meets modern protection standards at boxes, penetrations, and splices, supporting reliable power delivery over time.