Voltage drop is the quiet performance limiter in many homes, showing up as dimming lights, sluggish motors, warm cables, or electronics that behave erratically even when breakers never trip. Electricity must travel through conductors, connections, and devices, and every part of that path has some resistance. When current flows, that resistance causes a small voltage drop between the panel and the load. A modest drop can be normal, but an excessive drop can shorten equipment life, reduce efficiency, and reveal hidden wiring problems such as loose terminations or undersized conductors. Electricians measure voltage drop to confirm that circuits deliver stable power under real conditions, locate resistance hot spots before they overheat, and verify that new installations, such as EV chargers and HVAC equipment, will operate reliably.

What voltage drop testing shows

Voltage drop reveals how hard a circuit is working.

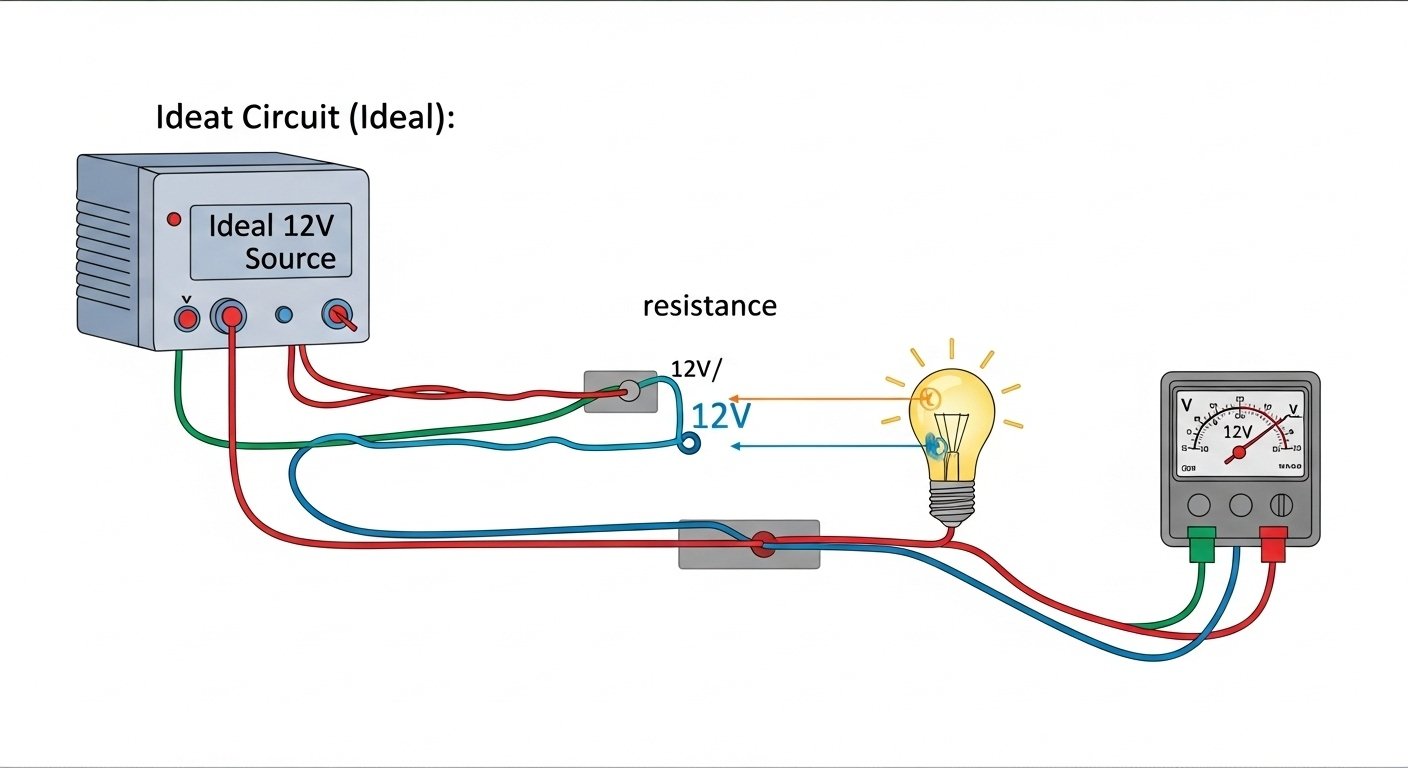

A voltage reading at a receptacle with nothing running can look perfectly fine, yet the same circuit may struggle when a load turns on. That is why electricians measure voltage drop under load. By comparing the voltage at the panel or breaker to the voltage at the farthest outlet or equipment connection while current is flowing, they can see how much energy is being lost along the way. Higher drop usually indicates higher resistance, longer conductor length, smaller wire size, or too many connections, which add friction to the electrical path.

It can also indicate that a circuit is being asked to deliver more current than it should, such as when multiple high-draw devices share a branch intended for general use. Measuring drop helps electricians evaluate whether a circuit is sized appropriately for its purpose, especially for longer runs to garages, outbuildings, or kitchen appliance locations. It also provides a numerical way to compare different parts of the home, showing which circuits are performing normally and which are under stress, even when symptoms are intermittent.

It helps locate loose connections and hidden resistance points.

Voltage drop testing is also a diagnostic tool for finding loose or damaged connections that may be hidden behind outlets, in junction boxes, or at the panel. A loose termination behaves like a resistor, heating up under load and creating a larger voltage loss across that point. Electricians often test at multiple locations along the circuit to narrow down where the drop increases sharply. If the voltage is stable at the first outlet but drops significantly at the second, the fault is likely between the two or at the second device. This technique is especially useful when problems come and go, such as flickers when a refrigerator compressor starts, because the momentary surge reveals weak connections.

Crews working on Electrical Services in Lansdowne often use load-based drop readings to distinguish between a device problem and a wiring problem, since a failing appliance can draw unusual current. In contrast, a wiring defect causes a drop even with normal current. Once the high-resistance point is found, electricians can re-terminate conductors, replace worn receptacles, correct backstab connections, or repair damaged splices before the issue escalates into overheating or arcing.

It protects motors, electronics, and sensitive equipment.

Many household devices are sensitive to voltage stability. Motors in HVAC blowers, refrigerators, pumps, and shop tools can run hotter and draw more current when the voltage is low, increasing wear and shortening motor life. Electronics such as computers, chargers, and smart home devices may reset, glitch, or fail prematurely if voltage sags during normal operation. Voltage drop measurement helps ensure that dedicated circuits for equipment are actually delivering the required voltage at startup and during steady operation.

This matters for equipment with high inrush current, where a long run or undersized conductor can cause a sag that prevents a motor from reaching speed quickly. That slow start increases heat and strain. Measuring drop also informs decisions about conductor upsizing for long runs, adding a subpanel closer to loads, or separating loads so that one device starting does not affect another. In practical terms, voltage drop testing is part of making a home feel reliable, ensuring that lights do not dim when the dishwasher starts, and tools do not bog down when used at the far end of a garage circuit.

Voltage drop shows circuit health

Electricians measure voltage drop across circuits because it reveals how well a circuit delivers power under real load and where resistance is stealing voltage and creating heat. Drop testing helps identify undersized conductors, overly long runs, overloaded branches, and loose connections that can cause flicker, nuisance behavior, and overheating risk. It also protects motors and electronics by confirming that voltage remains stable during startup and steady operation. For new installations, voltage drop readings validate that the design will perform reliably and support future load growth without hidden stress. By combining measured drop with targeted inspections and repairs, electricians improve both comfort and safety, turning a system that barely works into one that runs steadily and predictably.